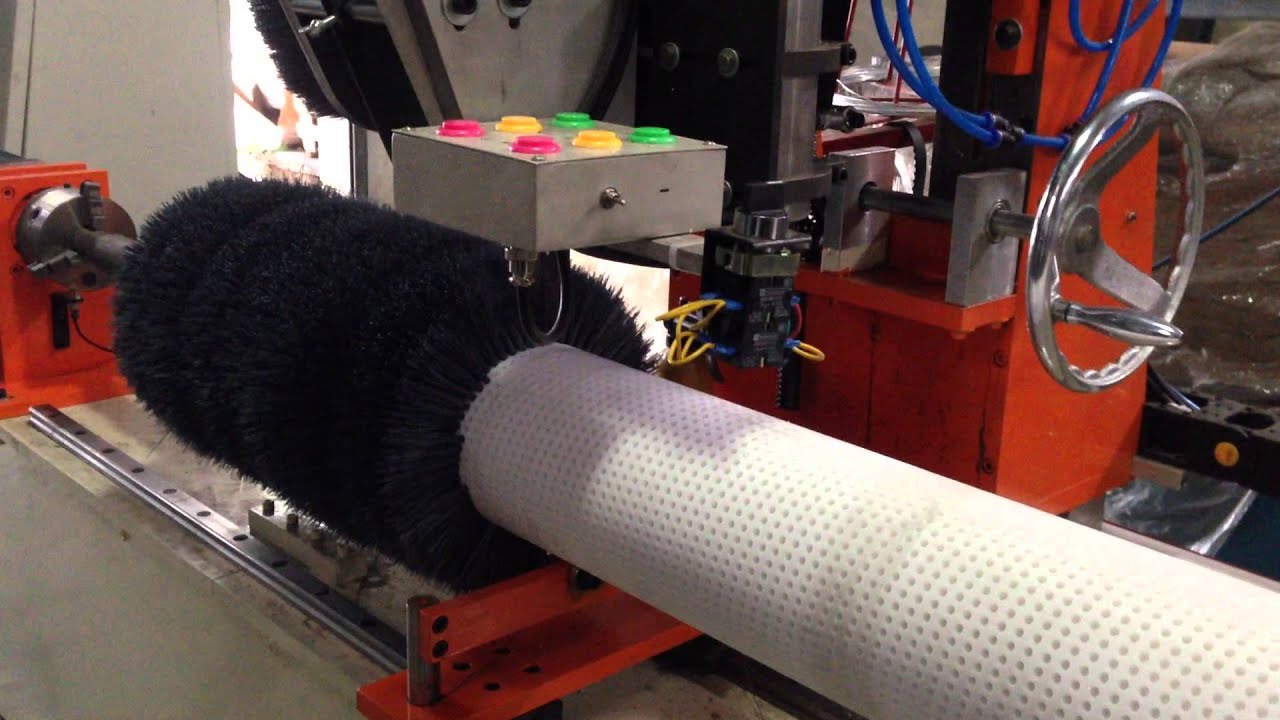

The machine is designed to tuft brushes made from synthetic fibers or steel flat wire with only one tufting tool and drill. The machine also offers a choice between different feeding systems: a fiber stock box for the fiber or a spool-fed system with double unwinder for the steel flat wire.

The brush making machine has a cam follower 163 which is affixed to and driven by the shaft 172 that makes one revolution for each tuft that is set by the machine. The cam 170 includes a portion of reduced radius in order to permit clockwise movement of the arm 157 and corresponding counter-clockwise movement of the arm 152, thereby rotating deflector 120 outwardly or toward the front of the machine. This movement of the tuft deflector is desired when a back such as back 22 (FIG, 2) is to be tufted.

When the cam is shifted to position it to operate upon a new brush back the jaws are lowered and a tuft of bristle strands is secured in an aperture of the back. A cutter is then used to sever an anchor wire from the strands. The anchor and strands are then passed through a tuft deflector that cooperates with the jaws to prevent interference therewith by previously set tufts. The jaws are then raised to the normal position and a different tuft of bristle strands are secured in a different aperture of the brush back. The anchor wire is then cut from the strands and the tuft deflector is shifted to be freed of the previously set tuft.

As the jaws move toward and within a tuft of bristle a drive needle secures the strands in the aperture of the brush back. As the needle is moved to its normal position it sever’s an anchor wire from the strands and the strands are then pass through an aperture in a tuft deflector that cooperates therewith to prevent interference with previously set tufts. The tuft deflector is then shifted to be freed of the previously inserted tufts and the jaws are then raised for repeat of this operation.

This process allows the machine to produce a large number of toothbrushes at an extremely high speed. Moreover, this technology provides a significant advantage for production in terms of design, cost and quality. It enables a variety of new brush shapes and can be applied to the most diverse types of handles.

PTt is a revolutionary technology which allows the production of anchorless toothbrushes. The toothbrushes are produced on existing standard toothbrush molds, thus avoiding expensive processing of the handle components. Furthermore, the tufts are secured without anchor wire, which significantly reduces the manufacturing costs and increases the output. Consequently, the production of toothbrushes using this technology is much more economical and environmentally friendly than conventional anchor-based methods. This innovative approach to the manufacturing of brushes is expected to revolutionize the industry. PTt’s unique technology will enable the production of a wide variety of toothbrushes, including new shapes and designs for both consumer and industrial use.