Hydraulic cutting machines are a great option for businesses that need to cut large quantities of material. However, they can have high upfront costs and require a lot of maintenance. It is important to understand these issues before selecting a manufacturer.

This machine is equipped with central automatic lubrication system, which can reduce the wearing of moving parts and prolong the service life.

High-speed cutting

A hydraulic cutting machine is a powerful tool that allows workers to cut different types of materials. It has the ability to cut metals, wood, paper, and plastics with precision. Its versatility makes it an essential part of any industrial workplace.

The hydraulic cutting machine is also capable of high-speed cutting, which increases productivity and efficiency in production processes. Its high-speed cutting capabilities can be attributed to the hydraulic cylinder that pushes the lower blade against the shearing surface to perform the cutting operation.

When choosing a hydraulic cutter, look for a reputable manufacturer with an established reputation. Factors to consider include production capacity, quality control, certification, and after-sales service.

In addition, look for a hydraulic cutting machine with safety features that are easy to identify and operate. These features will help protect operators from potential hazards and prevent accidents. They will also help ensure the longevity of the machine. Lastly, consider the price of the machine to make sure that it fits within your budget.

High-precision cutting

Many construction crews and manufacturers rely on hydraulic cutting machines to sever steel rods, chains, wires, cables, and other materials. These machines require a high level of precision and accuracy, so it is important to choose a manufacturer with a good reputation. This will ensure that your machine is durable and reliable, and it will also help you save money on repair bills in the long run.

Hydraulic cutters are similar to guillotine metal shearing machines, but they cut materials rather than bend them. They use a hydraulic mechanism to close the hardened steel blades of the scissors, and they are designed to be used on thicker plates.

Using a hydraulic cutting machine can be dangerous, so it is important to follow safety precautions. Before starting shearing, check the power supply, clutch, and brake for any signs of abnormal failure. If you find any signs of trouble, shut down the equipment and inform maintenance personnel.

Low-maintenance

A hydraulic cutting machine can be used to cut a variety of materials, making it ideal for any manufacturing project. It is easy to use and requires little maintenance, which helps to reduce downtime and costs. These machines also provide a high level of accuracy, which makes them perfect for creating intricate designs and shapes.

These machines can be purchased in several formats, including as attachments to power drills or as stand-alone units. They can also be powered by battery power for additional flexibility. This allows manufacturers to easily take their work to the jobsite and complete projects without relying on a generator.

When selecting a hydraulic cutting machine, it is important to consider the manufacturer’s reputation and production capacity. A reputable manufacturer will have the capability to produce quality machines and will offer adequate after-sales support. You can find out more about a manufacturer’s reputation by reading reviews from previous customers. You should also look for a manufacturer that offers an array of different models to suit your business’s specific needs.

Easy to operate

A hydraulic cutting machine is a powerful tool that can cut and shape various materials. It is easy to operate and can be used by workers of all ages. However, it is important to know how to operate this machine properly and safely. It is essential to wear protective equipment and follow the manufacturer’s instructions for safety.

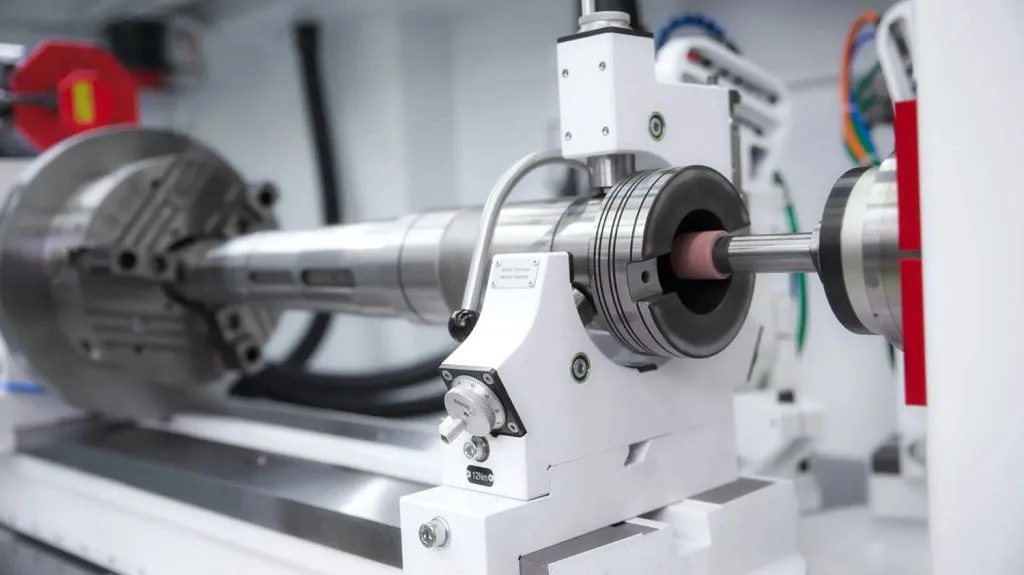

A hydraulic cutting machine is powered by a hydraulic pump and a hydraulic cylinder. The cylinder uses mechanical energy to move the blade, while the hydraulic pump converts mechanical energy into hydraulic energy. The resulting hydraulic force pushes the blade through the material, cutting it. The hydraulic cutting machine can be used for a wide variety of applications, including cutting metals and wood. It is also ideal for machining copper rails. It has a central automatic lubrication system that increases machine durability and extends its service life. The lubrication system is equipped with a high-quality piston and valve, which ensures reliable operation.