Machined parts are critical in the manufacturing of products like medical devices and automotive parts. They offer precise dimensions, tolerances and quality.

Finding the right shop for your machining needs is key to meeting your project deadlines. Whether you need a simple or complex machined part, here are some tips to help you find the right partner:

Invested Partner

Dedicated to providing customers with precision machine parts, this company offers engineering, design, fulfillment, sourcing and supply chain management services. Its build to print service offers rapid prototyping, low to high production runs and short lead times. Its capabilities include high-precision CNC machining, metal injection molding, casting, aluminum extrusion and sheet metal fabrication. It serves the aerospace, automotive, construction and military industries.

An ISO-certified company, it offers precision machine parts such as torque limiters. Its one-way or interactive clutches, magnet or compact limiters, one-way hinges and pressure rollers are used in electronics, mechatronics and chemitronics applications.

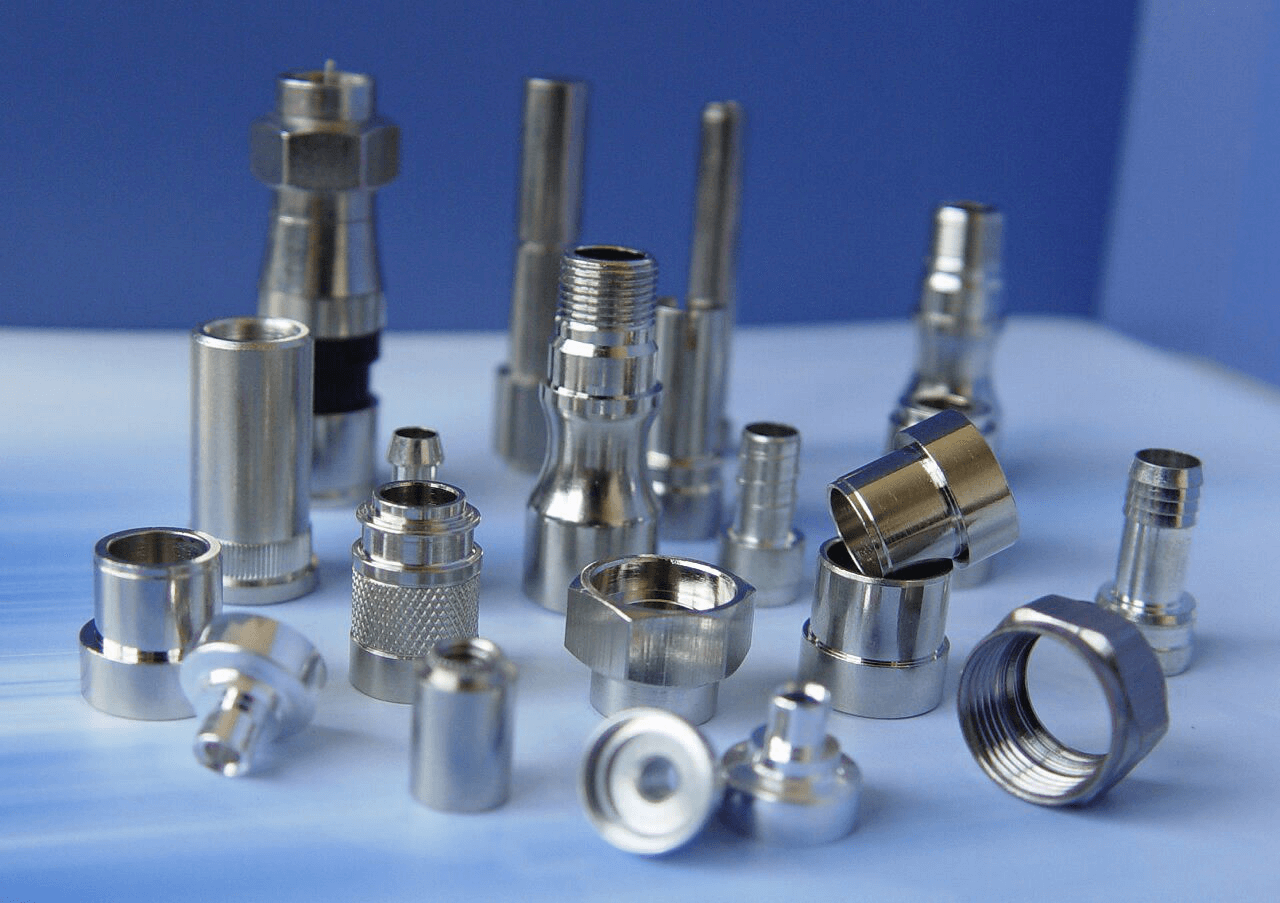

Its high-precision Swiss machined parts are held to tight tolerances. Their pins, inserts, terminals, shafts and specialty screws are used in medical devices and aerospace applications. Its custom manufacturing and lean manufacturing capabilities are available to customers through vendor managed inventory (VMI) programs. Various materials, including stainless steel, aluminum, brass and bronze alloys, are used.

Experienced Partner

CNC (computer-aided machining) machines create precise metal parts with less variation in dimensions and surface finish than manual cutting or die casting processes. Skilled machinists program the machine by using geometric information supplied in the form of a computer-aided design model. CNC machines can cut nearly any metal alloy or rigid plastic.

Custom manufacturer of a wide range of machined parts including bearings, bushings, cams, flanges, hinges and studs. Suitable for use in aviation, automotive, military, industrial and commercial industries. Blanket orders and low to high volume production runs accepted. Engineering, design and fulfillment services offered.

ISO 9001 certified manufacturer of machined parts. Services include CAD/CAM design, prototypes and lean manufacturing. Dedicated to meeting customer needs by providing accurate, on-time delivery of products and solutions. Various secondary operations available including deburring, knurling, sawing, grinding and polishing. Finished goods include screws, pins, plugs, seals, rings and stand-offs in metric and imperial sizes. Also carries out screw machining, laser marking and engraving, engineering, drafting, fixturing and project management.

Invested in Technology

Investing in technology to boost operational efficiency is important, but so is making sure that those investments are made in solutions that are compatible with business processes. Companies should also ensure that technology investments are scalable and flexible so that they can grow as the company does. It is critical that businesses take the time to evaluate existing technology, databases and systems to determine if a new technological solution will be compatible with current technology.

ISO 9001:2015 certified custom manufacturer of machine parts including bushings, collars, connectors, pins, shafts and spacers. Products are machined from carbon steel, copper, aluminum and bronze alloys. Machining services include boring, deburring, drilling, knurling, milling, reaming and turning. Services also include drafting, design review, fixturing, project management and tooling. Kanban delivery available.

Screw machined parts such as bolts, nuts, washers and studs are manufactured from a variety of metals including carbon, stainless and titanium. Products are machined to customer specifications and meet military and ASME standards.

Invested in Quality

As you do your research, look for a shop that’s willing to take responsibility for the quality of their work. A confident crew that stands behind every machined part is more likely to meet your future supply chain needs with speed and reliability.

An invested partner will communicate with you regularly and be available for questions or changes. They’ll be more receptive to addressing issues that arise during production and be proactive in identifying solutions.

A sheet metal shop customer recently outsourced the machining of six tight-tolerance parts to a local precision machine shop. When it came time to add the machined parts to the finished product, they discovered that the dimensions did not match. This meant that the parts were either machined incorrectly or the design was flawed. This was a costly mistake that could have been avoided with the right partnership. A supplier who invests in the quality of their work will minimize returns, complaints and rework that result in higher costs and lost profits.machining parts supplier