The straight shooters of the actuator world, electric explosion proof actuators transform electrical energy into linear motion. Designed to operate in hazardous gas and dust environments, they boast credentials like UL, ATEX, and IP68 weatherproofing.

They help automate quarter turn ball, butterfly and globe valves in industrial environments where flammable gases are a concern. They also incorporate fail-safe mechanisms that revert to safe positions in the event of a power failure or malfunction.

Safety

Electrical actuators are the core of most automated valve systems. They operate remotely, opening and closing the valve. At the same time, powerful electronics enable them to serve as information hubs for a wide variety of process and system diagnostics.

The actuation system is sealed in an explosion proof housing to ensure that the internal combustible mixture cannot leak through to the outside of the housing. It is also designed so that it will not become an ignition source within the hazardous area.

Explosion proof electric actuators reset to a fail-safe position in the event of power failure and offer excellent reliability, even in extreme environments. They are ideally suited for use in applications such as water treatment, ship,textile, and food processing.

Performance

Featuring explosion proof modules, this actuator helps ensure the safety of the valve and your project. It can be used with a ball valve, butterfly valve, or gate valve to help realize industrial automation and improve your project’s safety.

The EL-30 has an outstanding torque range that can handle any application. Exceptional switching speeds reduce energy consumption and emissions while improving control accuracy. With a wide selection of mounting options, you can install your EL-30 with ease.

Explosion proof electric actuators feature a variety of signal compatibilities, including on-off and modulating types that accept a 4-20mA input for valve positioning. They also include two auxiliary limit switches to confirm the valve position and thermal overload protection for enhanced safety. For added convenience, these actuators can be programmed without a HART communicator using a simple LCD display and self-calibrating function. These features are ideal for applications in hazardous environments.

Installation

Designed for use in hazardous gas and dust environments, these explosion proof electric actuators come with a wide range of features to fit your needs. They feature dual seals that isolate the circuit from external explosive environment, as well as flameproof enclosures to prevent sparks and heat during an internal explosion. They are also rated to operate over a wide temperature range, and withstand high levels of pressure during an explosion event.

They are available in rotary ‘Max’ (explosion-proof) and linear ‘Run’ (explosion-proof). They can be powered by AC or DC power, with the ability to reset to a fail-safe position during a power outage.

They are suitable for quarter-turn operation of ball valves (2″ and smaller), butterfly valves, plug valves, dampers, and similar applications. They offer visual and electrical valve position indication, manual override, and weatherproof enclosures. They are also available with an intrinsically safe type that uses an analog signal to control the output shaft position proportionally.

Maintenance

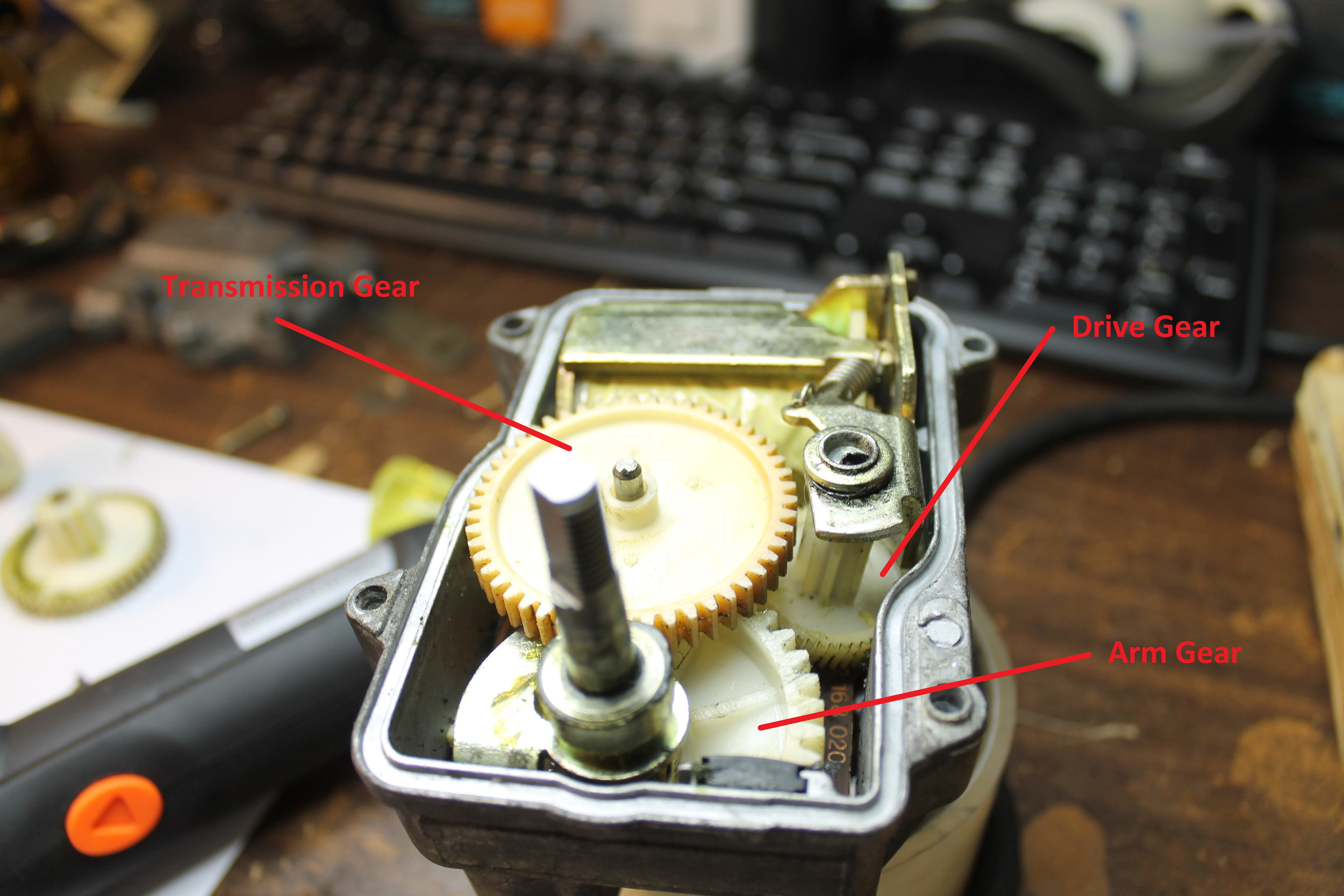

Electric actuators operate remotely, opening and closing industrial valves, and are used to control dampers and other systems. They are available in a variety of configurations and output torques to fit your specific valve application.

Explosion proof electric actuators feature a rugged design and meet strict electrical, mechanical and environmental standards. They are UL and CSA certified. They have two auxiliary dry contact limit switches to confirm open and closed valve position and a thermostatically controlled anti-condensation heater. They are also designed with a modular concept so you can select the best accessories and output options for your application.

In addition to providing command and control for the opening and closing of industrial valves, electric actuators can provide feedback data on system performance based on advanced self-diagnostics. This allows you to monitor and maintain your process. For example, the carbon brush in a flameproof electric motor may wear over time. When this happens, the actuator will alert you to replace it.Explosion-Proof Valve Actuator